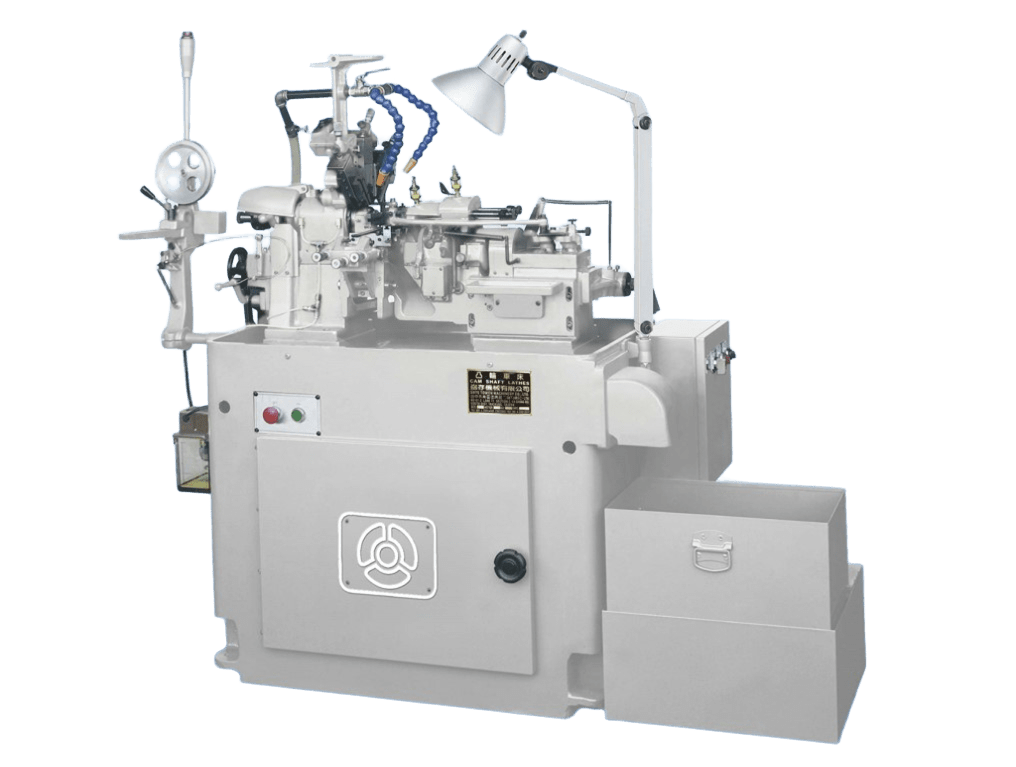

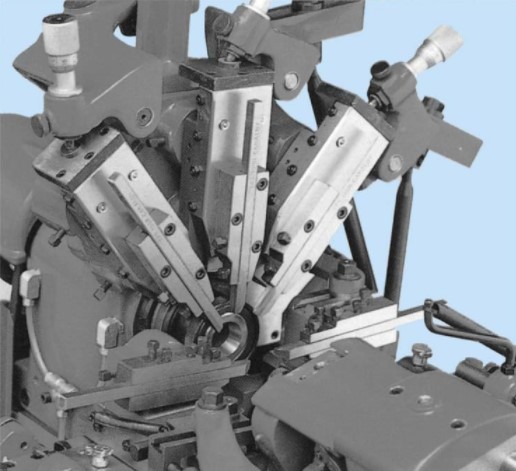

Spindle and tool holder

The spindle is made of special steel and has been subjected to high-frequency heat treatment and precision grinding. It is equipped with five sets of cutting tools and comes with fine-tuning screws, which can be used for high-precision turning work. The slide plate is made of high-grade cast iron, and the sliding surface has also been made of high-frequency heat treatment and precision grinding.

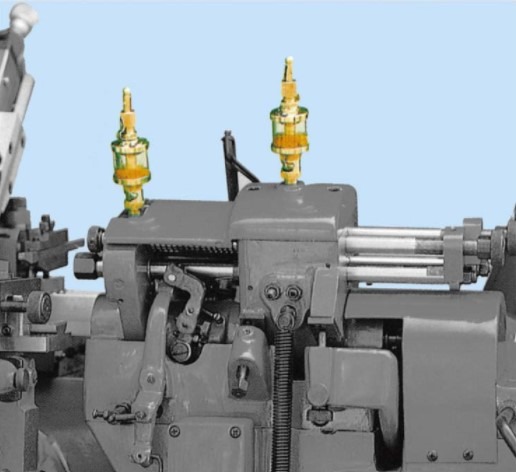

Two-axis device

This device uses an electromagnetic clutch to drive the tapping spindle, and utilizes the differential speed of high-speed rotation in the same direction as the mechanical spindle to perform tapping processing. The two axes can be oscillated for conversion processing. Reaming, drilling deep holes, and tapping can be completed at the same time.

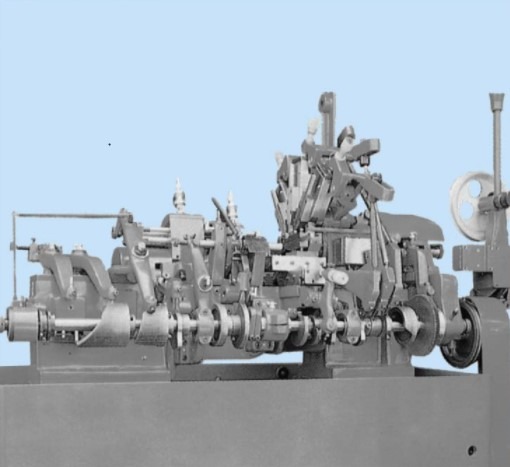

Cams and Camshafts

Plate cams are used for outer diameter cutting, and bell-shaped cams are used for rectangular cutting. The camshaft can be divided into two at the middle journal. The cams remain in their original shape and can be exchanged, so the combination change can be completed in a short time. It is highly efficient and can be adapted to various needs. Need to be converted to hand rotation.

| Type | STM-2025 |

|---|---|

| Number of tool holders | 5mm |

| Number of tail shafts | 2mm |

| Maximum processing diameter |  20mm 20mm 16mm 16mm 12mm 12mm |

| Maximum processing length | 35 mm |

| Maximum drilling diameter | ø10mm |

| Maximum drilling depth | 30mm |

| Maximum tapping diameter | (brass) M10 x 1.25 mm (Iron) M8 x 1.0 mm |

| Spindle speed | 1700 ~ 6500 rpm |

| Spindle speed conversion number | 5mm |

| Camshaft speed | 1.3 ~ 3.3 rpm |

| Spindle motor | 2HP |

| Cutting oil pump motor | 1/8 HP |

| Mechanical weight | 810kg |

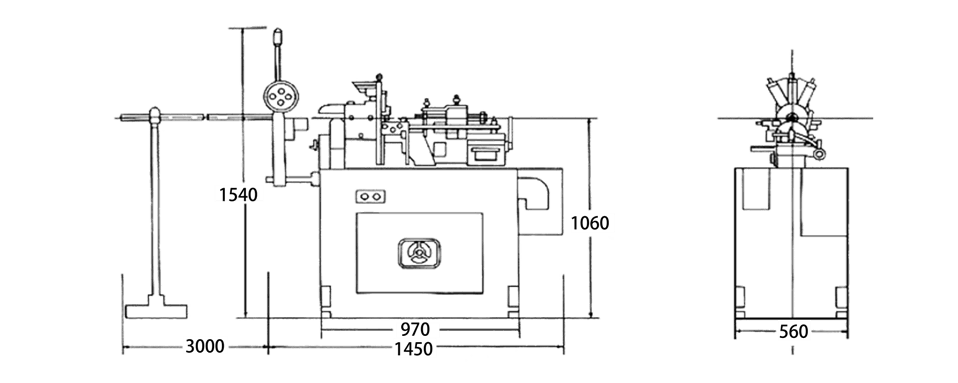

| Mechanical dimensions | 1450x560x1540mm |

| Packing size | 1720x740x1840mm |

* Our company conducts research and improvement work at any time, so we reserve the right to change the design, specifications, dimensions and mechanical structure at any time.

Tool movement diagram & tool interference diagram

| Standard equipment | Optional equipment |

|---|---|

| Anti-splash oil cover 1 set | Milling tooth seat |

| 1 set of adjustment tools | automatic feeder |

| 1 tool box | Trenching machine |

| 1 set of cutting cooling device | Feeding rack |

| Silk male jacket 2 pieces Ø20, Ø25 | Flexible collet |